Lightfastness

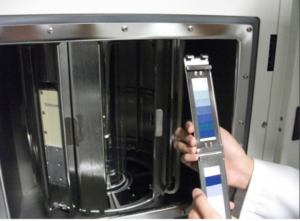

DIN EN ISO 105-B02, Textiles – Tests for colour fastness – Part B02: Colour fastness to artificial light: Xenon arc light, method 3, exposure level 5 to 8.

A textile sample is exposed under certain conditions to an artificial light source corresponding to natural daylight. The colour change resulting from this exposure is graded using a blue scale. Grades from 1 to 8 are given, 1 being the worst and 8 the best.