When you buy an expensive cashmere jumper, whether as a consumer or a retailer, you expect the stated cashmere content in it. If you buy a wool jumper, it should not turn out to be polyacrylic. Legislation has clearly stated that all textiles in the EU must be labelled and that labelling must be accurate to within 3%. If your labelling is different, your product can be taken off the market.

If, with a declared composition of 60% polyester and 40% cotton, your product actually contains 55% polyester and 45% cotton, it will already be deemed unfit for sale.

We can help you know what you are selling. We test for you and we know the labelling regulations. So we can tell you what to put on your label to guarantee a safe product.

Fibres can be roughly divided into two different types: natural fibres, which are harvested from nature, and synthetic fibres. Natural fibres include plant fibres such as cotton, linen, kapok, sisal and other plant fibres. Animal hairs are also natural fibres and used in textiles: wool, cashmere, angora, alpaca and many more. In addition, silk is used, which is an animal fibre, but not a hair, but a secretion.

In contrast to the natural fibres, synthetic fibres are artificially produced. The raw materials can still be of natural origin, as for instance in the case of viscose. Here, cellulose from wood pulp is used to produce viscose. Examples for well-known synthetic fibres, made of synthetic raw materials, are: polyester, poyamide, polyacrylic or polypropylene.

Recently, novel fibres are used more frequently. These include bi-component fibres. Elastomultiester is one of them. These fibres consist of two different areas within one fibre. The unique structure creates special properties. Elastomultiester, for example, acquires an elasticity that neither region would have on their own.

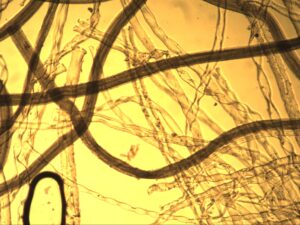

But how can these fibres be identified? Not all fibres look the same. Cotton fibres are twisted, linen fibers have nodes and a bamboo-stem-like structure, wool fibres have scales on the surface, and viscose fibres have longitudinal stripes. Most synthetic fibers are completely smooth but they differ in other ways. Polyester can be produced, for example, as a round fiber, as a flat, oval fiber, as a hollow fiber or in several other variants.

In the Textile Labelling Regulation 1007/2011, which stipulates the labelling of textiles in the EU, Annex I lists the types of fibers that may currently be present on a labelling. There are currently 50 types of fibres on this list. We can identify all common fibre types, and for instance distinguish cashmere from wool.

We mostly identify the fibre types by means of microscopy. In doing so, we use the methods described in DIN CEN ISO / TR 11827. At the same time, we use carefully validated in-house procedures that we have developed over our years in business.